Spray Drone Classes: What Size Is Right for You?

Spray drones are no longer a novelty that lives only in a few specialty corners of Agriculture. They now show up on row crop operations, vineyards, orchards, golf courses, conservation projects, wetlands, forestry work, and many other sectors. That variety is exciting, but it also creates a real challenge.

Most operators are no longer asking, “Can a spray drone do this at all” but instead, “Which spray drone class is actually the right tool for this environment”

That is where a practical way to classify spray drones becomes helpful. Not a legal classification. Not a marketing gimmick. A simple, field tested framework that matches platform types to the jobs and environments where they actually make sense.

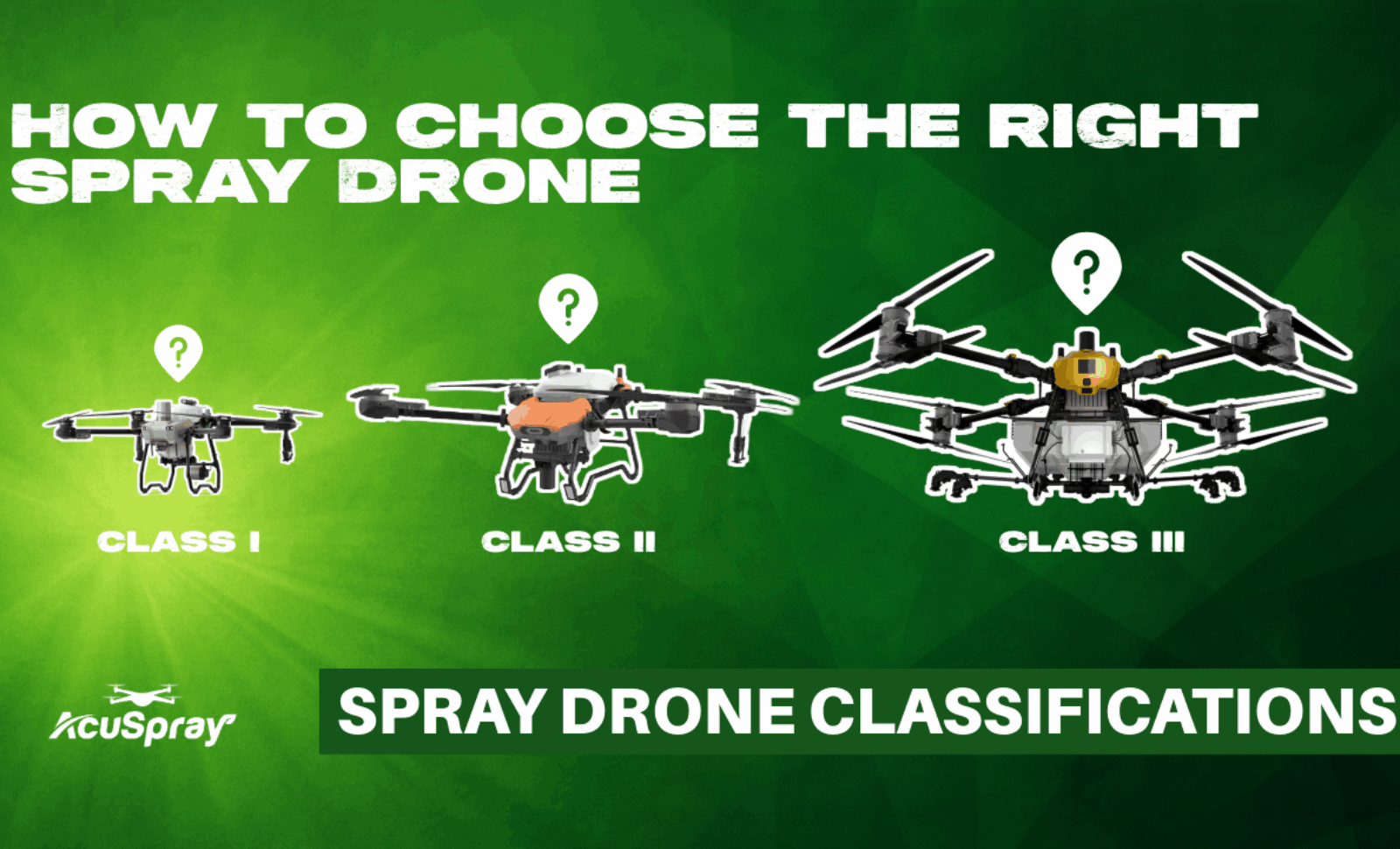

What follows is a three-class way of thinking about spray drones: Class I, Class II, and Class III. It is not meant to be rigid or final. It is a starting point, based on real work across agriculture, turf, and conservation, to help operators avoid mismatching tools to the environments in front of them.

If you’d prefer watching a video, check that out here:

From Spec Sheets to Real Environments

On paper, spray drones look easy to compare. Tank size, spray width, battery count, listed acres per hour, and so on. That data matters, but it does not tell the whole story.

In real operations, environments vary widely:

- Tight tree lines and narrow lanes

- Open square mile sections

- Marsh edges and irregular shorelines

- Rolling or hilly terrain

- Small odd shaped fields cut up by creeks, roads, and power lines

- Golf fairways, greens, and roughs with bunkers, trees, and water

- Conservation plots with different vegetation, slopes, and obstacles packed together

Once these environments come into play, it becomes clear that not every drone is built for every job. Two platforms with similar gallons and similar spec sheets can behave very differently when obstacle avoidance, braking distance, and turn radius are involved.

That is why thinking in “classes” can be so helpful. Instead of asking, “What is the biggest drone my budget can handle” the better question becomes, “Which class of spray drone is the right match for my specific environments and workflows”

The framework below uses three broad categories based roughly on tank size, then refines them based on how the aircraft actually operates in the field.

Class I Spray Drones: Small, Agile Problem Solvers

Class I spray drones are smaller platforms, generally under about 10 gallons of capacity. In the current market, this would include platforms like the DJI T25 or T25P and the ABZ L30, along with similar models from other manufacturers in the same size range.

The defining feature of Class I is not gallons. It is agility.

These aircraft are built to work in complex, obstacle heavy environments where the ability to maneuver matters more than raw throughput. Class I drones shine when the job asks for careful, precise flying in tight spaces, rather than maximum acres per day.

Where Class I Shines

Typical Class I environments include:

- Golf courses with trees, water, bunkers, and cart paths

- Sports turf on campuses or stadium complexes

- Conservation and wetlands projects with irregular edges and mixed vegetation

- Aquatic work around ponds, shorelines, and marshy areas

- Cemeteries, parks, and campuses with dense obstacle layouts

- Smaller fields with lots of “nooks and crannies” and irregular shapes

In these settings, the physical footprint and handling characteristics of the drone matter just as much as capacity. Smaller drones can slip into tighter corridors, stop more quickly, and navigate around trees and structures that would be off limits for a larger platform.

A key factor is obstacle avoidance behavior, especially braking distance. A Class I spray drone like the T25 can often allow a shorter stopping distance before it halts itself in front of a tree or object. Larger aircraft typically maintain a bigger protective “bubble” around the airframe, which means they have to begin braking much farther from obstacles.

In practice, that bubble can be the difference between “this drone is usable here” and “this drone cannot physically complete this job in a safe, efficient way.”

Strengths and Tradeoffs of Class I

Strengths:

- Excellent maneuverability in tight and complex spaces

- Shorter braking distances and tighter obstacle avoidance envelopes

- Easier to justify in operations that focus on smaller but more complex jobs

- A natural fit for golf, aquatics, conservation, urban or campus environments

Tradeoffs:

- Lower throughput on large, open acreage compared to bigger platforms

- More trips for refills when treating larger contiguous fields

- Operators must accept that some larger agricultural jobs may take longer or require additional support assets

The key point is that Class I spray drones do not “win” on gallons. They win on agility and practicality in environments where nimble, precise flying is far more valuable than raw capacity.

Class II Spray Drones: The Mid Size Workhorses

Class II spray drones sit roughly in the 10 to 20 gallon range. Current examples include platforms like the DJI T40/T50, the Exedy Ayre CX, the XAG P150, and the EAVision J100/J150.

In many regions and sectors, this is the class that fits the largest number of operators most of the time. While no drone is a true “Swiss Army knife” that does every job perfectly, Class II Spray Drones often come the closest to an all around workhorse.

The Balance That Makes Class II So Attractive

Class II spray drones hit a sweet spot between several competing factors:

- Throughput: Enough capacity and spray width to move real acres at commercial speeds

- Maneuverability: Still compact and agile enough to work around many obstacles

- Logistics: Batteries, chargers, support trucks, and mix systems that are robust but not overwhelming

- Transport: Easier to haul from site to site than the largest platforms

- Cost: A balance between initial investment and earning potential over a season

For many AcuSpray operations in agriculture, Class II Spray Drones are the default choice. This applies across a wide variety of crop types:

- Row crops such as corn and soybeans

- Specialty crops such as vegetables, orchards, and vineyards

- Mixed operations with a blend of open fields and more constrained areas

In these scenarios, Class II Spray Drones are often large enough to make acres but still small enough to thread around trees, pole lines, end rows, and other on farm obstacles.

Geography and Field Structure Matter

The ideal class is not the same everywhere. Geography, field size, and field shape change the equation.

Consider a few contrasting examples:

- In regions with wide open, mostly square mile fields and minimal obstacles, Class III might be the most productive choice because the environment allows larger platforms to run efficiently.

- In hilly or broken terrain, or areas similar to the hollers of Appalachia, Class I might be far more practical because of the tighter maneuvering and more complex obstacles.

- In many mixed environments with a blend of medium sized fields, tree lines, and typical Midwestern infrastructure, Class II tends to be the best match.

The important idea is fit, not size. Class II platforms give many operators enough capacity to move acres while keeping the aircraft manageable in the sorts of environments they see every day.

When Class II Overlaps With Other Classes

Because Class II sits in the middle, there is natural overlap:

- Class II drones can handle many Class I jobs, especially when the layout is tight but not extreme.

- Some Class II jobs could be done with a Class I platform, but would simply take longer.

- In large open fields with minimal obstacles, a Class III drone might outpace Class II on throughput, but only if the support logistics can keep up.

This overlap is not a problem. It is actually an advantage. When operators understand the strengths of each class, they can choose the aircraft that delivers the best mix of safety, efficiency, and practicality for a given day’s work.

Class III Spray Drones: Large Platforms for Big, Open Acres

Class III spray drones are the largest category in this framework, generally around 20 gallons and up. Current examples include platforms like the DJI T100 and the Ceres Air “Black Betty,” along with other large format aircraft that are starting to reach the market.

These are purpose built machines. They are not simply “better” versions of Class II drones or an automatic upgrade for any operator. They are designed for a different workflow.

Where Class III is an absolute game changer

Class III spray drones shine when the environment supports what they do best:

- Large, open acreage

- Long, straight lines

- Minimal obstacles and predictable terrain

- Wide, consistent headlands with room for turns and staging

- Strong logistics support for power, charging, and water

In such settings, Class III platforms can dramatically increase throughput. With large tanks, wide booms or spray widths, and efficient flight lines, they can “knock down the acres” in a way that smaller drones simply cannot match.

However, this performance only shows up when the operator’s logistics match the appetite of the machine. That means:

- Sufficient battery power and on site charging capacity

- Adequate water hauling and mix system capacity to keep the drone supplied

- Ground support staff who can maintain a steady cycle of mixing, loading, and swapping batteries

Without that support, a Class III platform risks becoming an expensive tool that spends too much time waiting and not enough time flying.

When Class III Becomes The Wrong Tool

The same characteristics that make Class III so powerful in large areas can make these aircraft unsuitable in tighter environments.

Imagine dropping a large spray drone into a 20 acre irregular field with trees on all sides, narrow entries, and obstacles scattered across the interior. If the aircraft’s obstacle avoidance requires it to begin braking 20, 25, or even 30 feet away from a tree, the drone may simply not be able to navigate the layout.

That reality limits where Class III platforms can be safely and efficiently used. Golf courses, campuses, cemeteries, and winding conservation sectors commonly fall outside the sweet spot for this class. In these environments, the aircraft’s protective bubble around obstacles becomes so large that the drone loses too much of the usable field.

Class III spray drones are excellent at what they are designed for. They can be transformational in big, clean fields. But they are not universal tools, and they should not be treated as automatically superior to Class II or Class I platforms.

Overlap, Gray Areas, and Mixed Fleets

The real world is messy. Jobs seldom fit neatly into perfect boxes, and spray drone classes are no exception.

There will always be Class I jobs that a Class II drone can handle just fine. There will be Class II jobs that a Class I can complete, only more slowly. There will be agricultural environments that appear identical in a map view but behave very differently once a drone starts flying them.

For example:

- Two fields might have the same acreage, but one has clean edges and simple rows while the other has tree fingers, waterways, and irregular corners.

- A small conservation project might be physically close to an open agricultural field, but the topography and obstacles demand completely different aircraft behavior.

Because of this, it is helpful to treat Class I, II, and III as lenses, not rigid buckets. They provide a mental model for how different aircraft behave in different environments, so operators can ask better questions when planning an operation or buying their next platform.

For custom applicators in particular, a mixed fleet can make a lot of sense. A single high throughput Class III platform may dominate large open crop fields, while a Class II drone covers mixed agriculture and a Class I drone handles golf, aquatics, and conservation work.

In that kind of fleet, the operator is not guessing or forcing every job into the same tool. Instead, the operator can:

- Match each environment to the class that fits it best

- Use Class II as the “bridge” platform where there is overlap

- Deploy Class I where agility and precision matter most

- Reserve Class III for the acres that truly justify its logistical demands

Key Takeaways and Next Steps

- Spray drones now work across agriculture, turf, conservation, and many other sectors, which means environments vary widely.

- The “biggest drone possible” approach is risky. Not every aircraft fits every job.

- A practical three class framework helps operators match platforms to real conditions:

- Class I: Small, agile platforms under about 10 gallons, ideal for tight, obstacle heavy environments.

- Class II: Mid size workhorses in the 10 to 20 gallon range, often the best match for mixed agricultural acres.

- Class III: Large platforms around 20 gallons and up, purpose built for big open fields and strong logistics support.

- These classes overlap. They are lenses to think with, not rigid boundaries.

- Many custom applicators benefit from a mixed fleet, so they always have the right tool for the conditions in front of them.

Before committing to a platform, operators can ask a few key questions:

- What does a “typical” job look like in terms of acreage, field shape, and obstacles

- How common are tight environments like tree lines, shorelines, small irregular fields, or golf course style layouts

- What level of logistics support is realistic for batteries, charging, and water hauling

- Is there a plan to expand into other sectors such as turf, aquatics, or conservation where smaller or more agile platforms may be essential

AcuSpray uses this kind of framework every day to plan flights across agriculture, golf, and conservation sectors. It is not about chasing the newest spec sheet. It is about pairing the job, the environment, and the logistics with the right class of drone so that operations are safe, efficient, and sustainable over time.